Breakthrough Composites Manufacturing - Large Scale, High Volume, Low-Cost

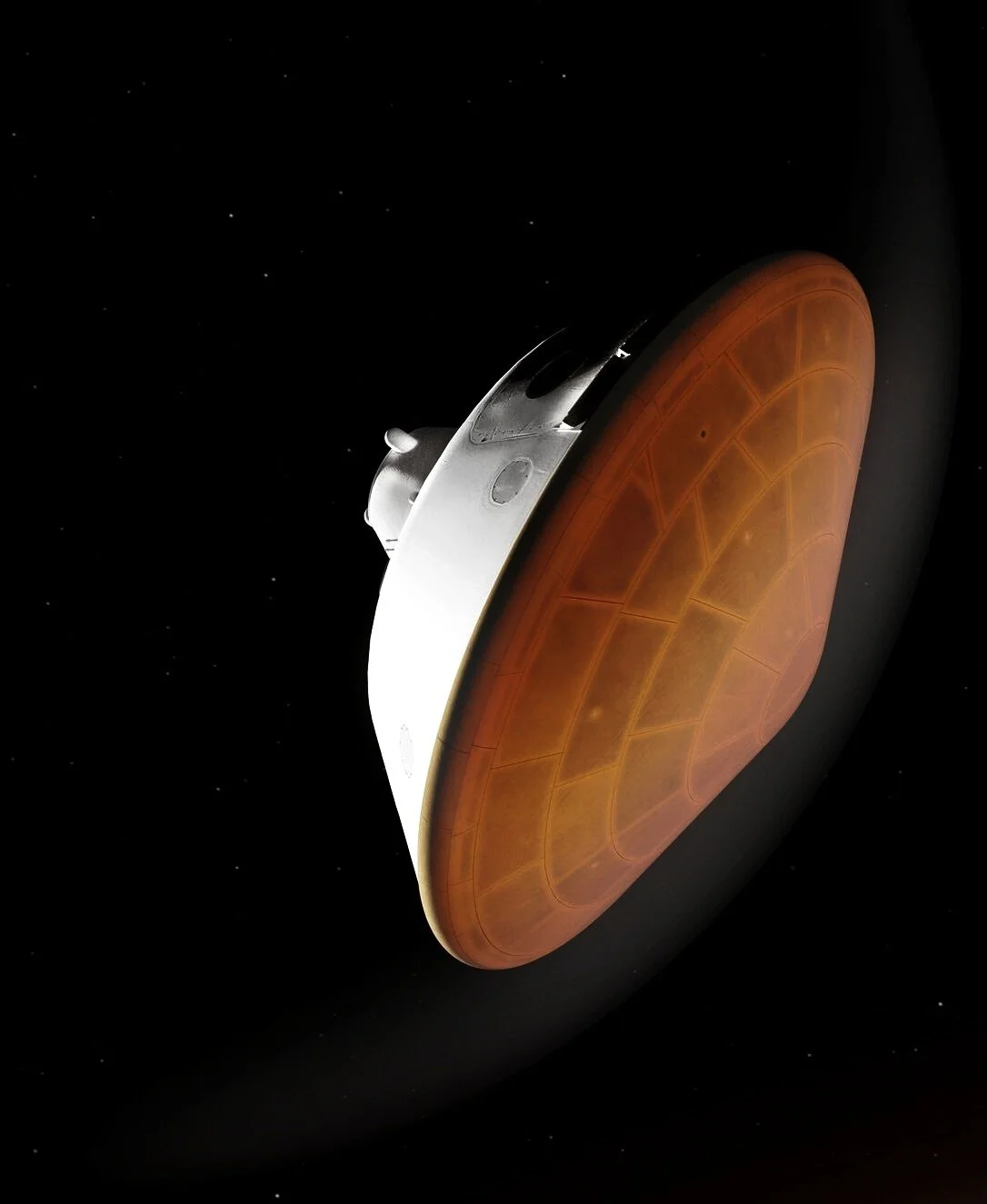

Thermal Protection Systems

Empower the deployment of reusable rockets and advanced planetary exploration technology

From Mars to Earth

Thermal Protection Systems (TPS) are essential for protecting the technology and astronauts that will launch humanity into our next phase of space exploration. However, TPS manufacturing is laborious, slow, and expensive.

That’s where we come in.

Make Larger

3D print large sections of the heat-shields all in one piece, through robotic automation and continuous-fiber printing. ISAM removes cost and logistical barriers while enabling us to make even larger heat shields directly in space

Make Better

Advanced 12-axis multi-robot tool pathing creates better TPS with topology-optimized placement of AM continuous fiber. Higher fiber density = higher performance and lighter weight, simplifying difficult missions like Mars Sample Return.

Make Faster

Combine Robotic Continuous-fiber Additive Manufacturing and Compression Molding (link to AMCM page) to make heat-shield tiles with automotive-style high-volume production while meeting the most stringent TPS requirements.

Break the Aerospace Manufacturing Bottleneck

Direct-to-Phase II SBIR award

In-space Service, Assembly and Manufacturing (ISAM)